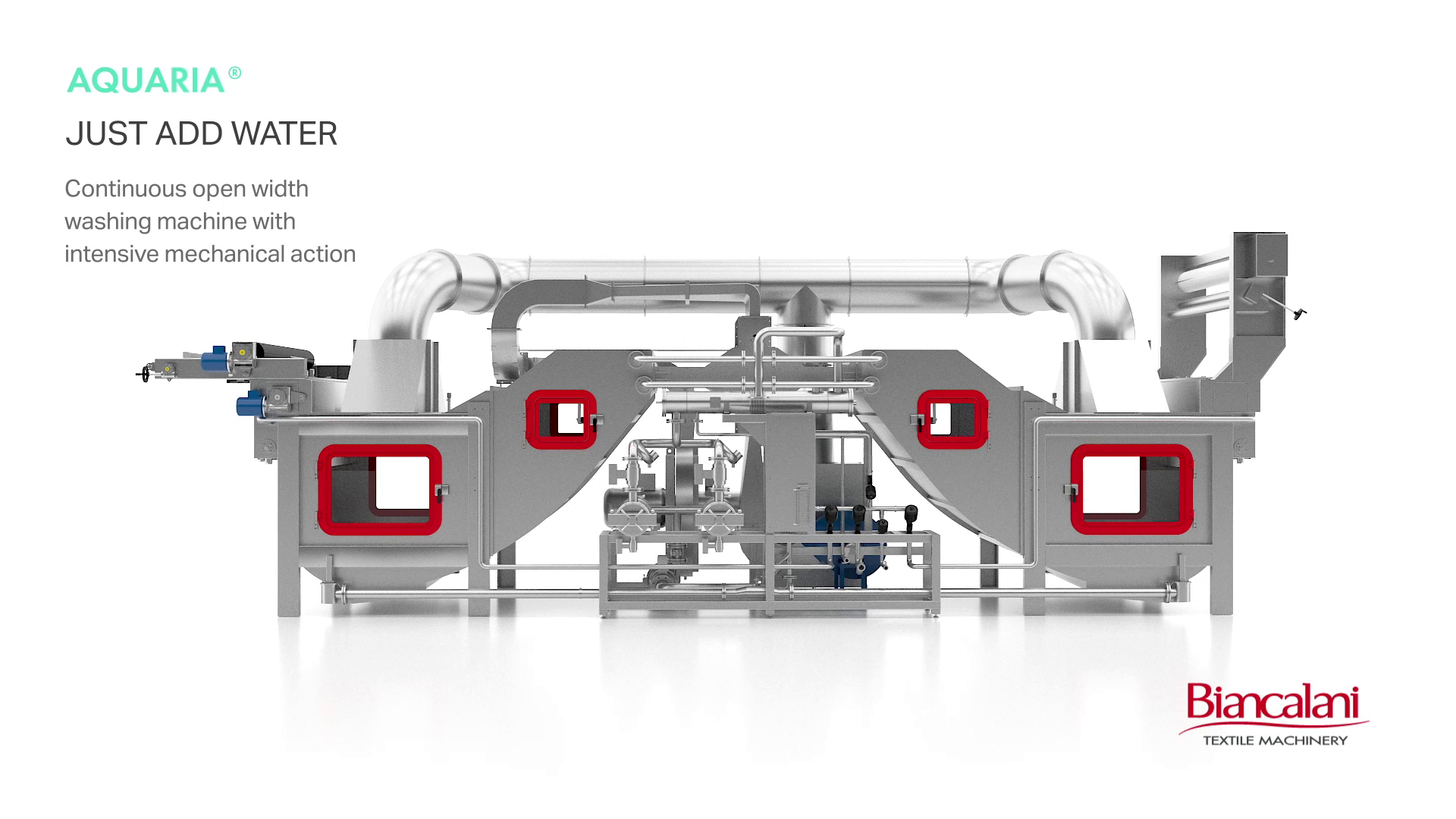

AQUARIA®: open-width versatility, sustainability, and performance in continuous fabric washing

In the increasingly competitive landscape of the textile industry, where environmental sustainability and production efficiency are no longer options but necessities, Biancalani presents AQUARIA®, the continuous open-width washing system that establishes new reference parameters. This patented solution represents the culmination of years of innovation and research, offering unprecedented performance in treating every type of fabric.

The DNA of Innovation: patented technology at the service of sustainability

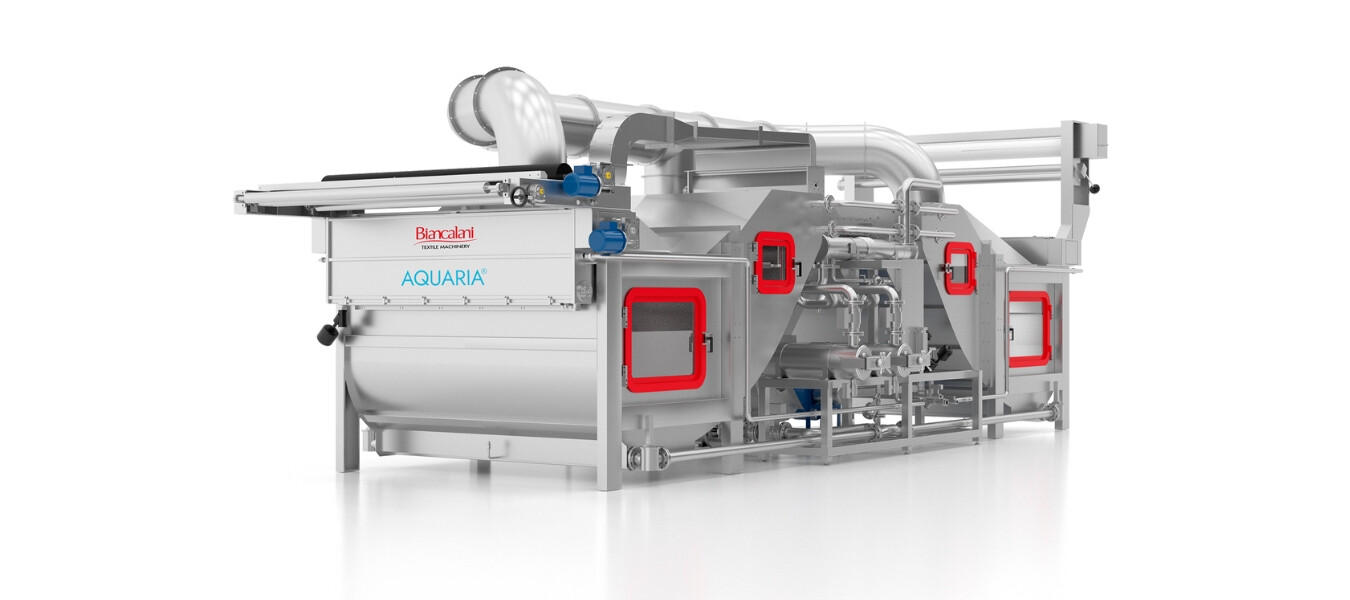

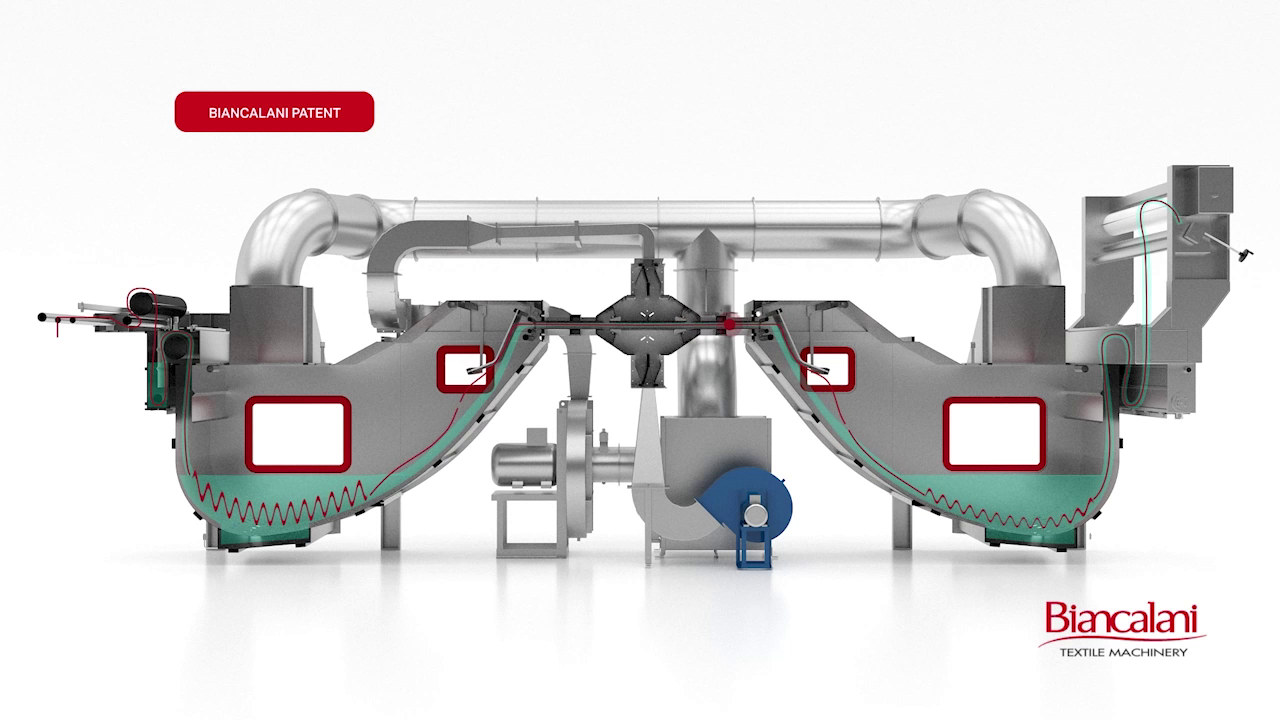

AQUARIA® is not simply a fabric washing machine: it is the result of an unprecedented vision that combines Biancalani's consolidated experience in fabric transport by air, with the most advanced wet treatment technologies. The system, protected by several international patents, represents the only solution capable of simultaneously offering extended and adjustable dwell times together with effective mechanical action, in a safe and continuous open-width process.

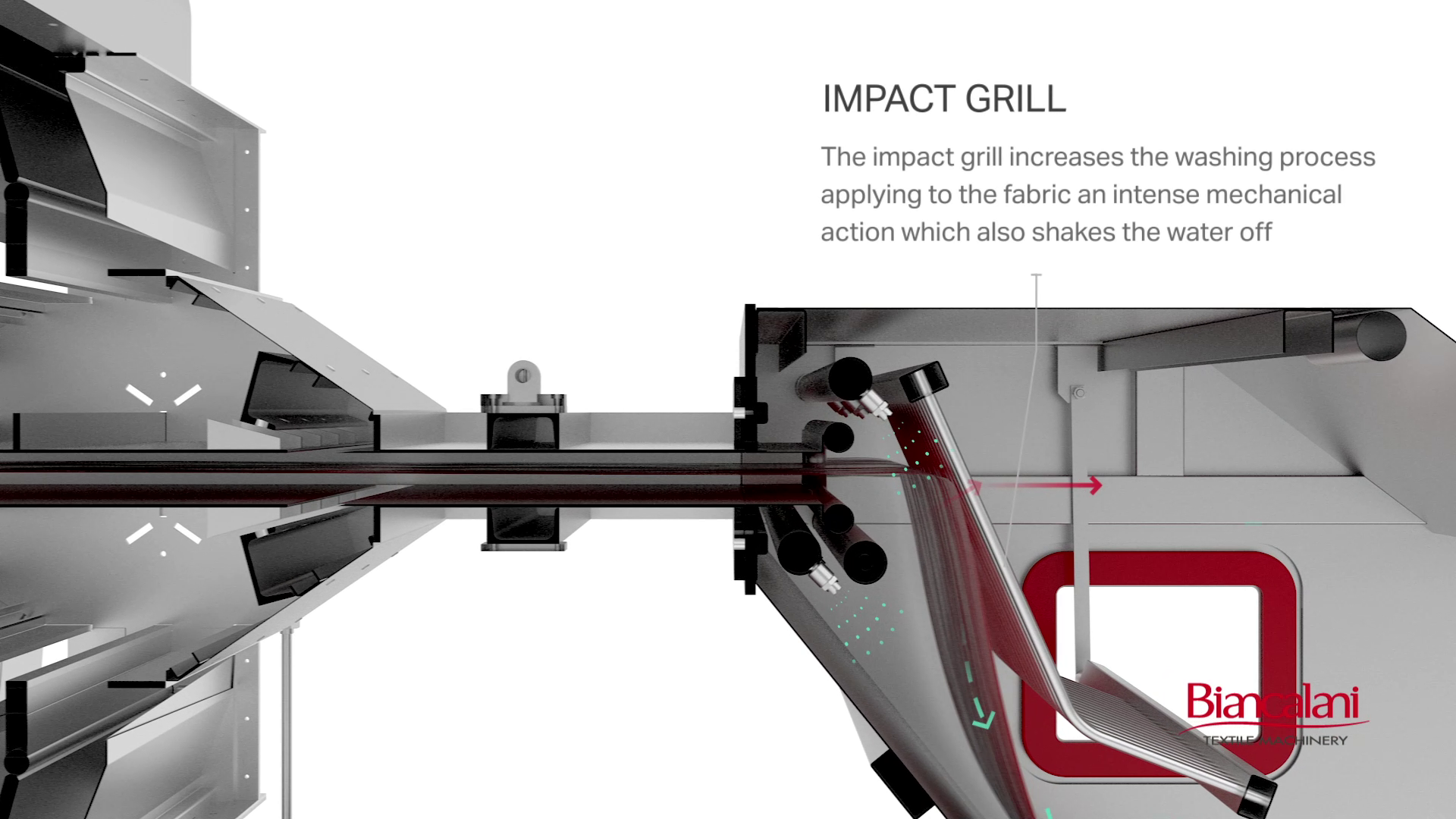

The technology is based on the AIRO® concept of fabric movement exclusively through air, applying true mechanical action during washing. Two large accumulation chambers, connected by a pneumatic ejector with impact grids, allow the fabric to move at high speed and accumulate immersed in the process bath, while continuous nebulization keeps the fabric permanently and uniformly wet.

Quality Assurance Guarantee

All AQUARIA® treatments ensure 100% safe and defect-free processing, completely free from any wrinkles or crease marks, maintaining fabric integrity throughout every process cycle.

Application versatility: a system for every fiber and application

Industrial tests on production scale have demonstrated the compatibility of the AQUARIA® system with the extraordinary breadth of its applications, effectively treating a wide range of fabric compositions. The system manages with the same excellence a wide range of materials, including cotton and blends, linen and blends, lyocell, cupro (cuprammonium rayon), modal (including faux cupro effect), synthetic fibers such as polyester and blends, polyamide and acrylic, as well as noble fibers like silk and wool.

The versatility of AQUARIA® extends to all major application sectors. In the apparel sector, the system effectively treats shirting fabrics, workwear, technical-sportswear, and knitwear, with weights starting from 50 gsm and up. For the home furnishing sector, AQUARIA® handles heavier products such as mattress covers, sheets, bath towels, and upholstery fabrics, with weights up to and exceeding 800 gsm. The system also finds application in the automotive sector, treating specialized technical fabrics in any construction.

A comprehensive portfolio of treatments and processes

The excellence of AQUARIA® manifests in its extraordinary application versatility and comprehensive range of specialized treatments, which the system manages with the highest efficiency.

Advanced enzymatic treatments which combine effectiveness with productivity

Whether used for bio-polishing (removal and prevention of pilling formation), or for special fashion effects such as aged look, washed-out color (délavé), or peach skin effects, the enzymatic treatments in AQUARIA® are performed with maximum precision, guaranteeing perfect results together with a special hand feel of the fabric.

Laboratory and production tests have confirmed effectiveness of the bio-polishing on cotton and cellulosic fabrics for complete elimination of pilling and a perfectly smooth and clean surface, and for the processing of modal and lyocell aimed to pilling prevention, as part of a full fibrillation-defibrillation process.

Key advantages include 100% green processing, in a relaxed and safe treatment, with extremely low water consumption, and significant improvement in fabric final hand and feel.

Fully sustainable eco-bleaching with zero water discharge

A revolution of the traditional bleaching process, the eco-bleaching treatment in AQUARIA® uses zero caustic soda, zero liquid peroxide, zero chlorine, and works in a closed cycle without effluent discharge (zero-water) for a 100% green process.

Applicable to cotton, lyocell, and any cellulosic fiber, and with a cost which is comparable to the traditional bleaching, this process represents a breakthrough in sustainable textile processing, as it guarantees perfect results while also improving fabric handle.

As a further advantage, this process can be combined in most cases with the desizing process, and for specific requirements, also with the application of optical bleaching agents.

Dedicated to indigo processing: AQUASTONE and AQUA+FLAT

For reduction of indigo shade on denim fabrics, AQUARIA® offers the specially-developed AQUASTONE treatment, which achieves up to 50% reduction of the original shade while providing benefits in terms of width and warp shrinkage. This process maintains the same green credentials with zero harmful chemicals and low water consumption, allowing to safe a huge amount of water during the garment washing stage.

Additionally, AQUARIA® provides comprehensive indigo washing and fixing processes for any indigo-dyed denim fabric, such as the AQUA+FLAT treatment. The system delivers cost-effective flat finish enhancement while maintaining 100% green processing standards. Key benefits include chemical fixation to keep colors dark with better crocking resistance, quick washing to remove dust and unfixed indigo, dimensional stability through width and warp shrinkage control, and improved fabric hand and feel.

Complete treatment of Lyocell from preparation to finishing

The AQUARIA® system applies an integrated treatment that includes mechanical fibrillation of fibers and subsequent enzymatic washing. This double process eliminates the tendency to pilling and gives the fabric a soft and pleasant handle, following established industry guidelines from leading Lyocell fiber producers, with measurable improvements in pilling and dimensional stability.

AQUARIA® offers specialized Lyocell preparation following industry-standard recommended procedures. This treatment, applicable directly on loom-state fabric, implements comprehensive preparation for anti-pilling and special hand touch effects. The process features low water consumption, relaxed processing conditions, and significant improvement in fabric final hand, feel, and appearance.

Dedicated alkaline or acid fibrillation

The fibrillation process, which is part of the Lyocell preparation, can be successfully applied, both in alkaline and acid conditions, also on any other cellulosic fabrics, including cupro, and modal. In particular, on polyester-modal fabric, both knitted and woven, AQUARIA® can be used to obtain an effect which appears very similar to the one which is obtained on cupro fabric.

Relaxed mercerization for unique hand feel

AQUARIA® introduces relaxed mercerization capabilities for denim and woven fabrics in cotton/cellulosic fibers. This innovative process delivers special hand feel characteristics, while at the same time improving dimensional stability. The treatment provides a unique hand and touch profile different from traditional mercerization, achieved through relaxed processing with low water consumption and controlled width reduction and warp shrinkage.

Desizing and scouring, effectively and efficiently

The system can perform desizing from starch, PVA and any other sizing agent, as well as washing and scouring of any fabric, always obtaining perfect results. The high washing efficiency of the mechanical action, combined with the air transportation of fabric, allows the system to save considerable amounts of water and chemical products, while at the same time reaching high figures of productivity.

Specialized organic scouring (oil removal) from synthetic fibers

For synthetic fabrics, AQUARIA® provides comprehensive organic scouring solutions for a 100% green process which entirely eliminates any solvent while effectively removing weaving and knitting oils. The treatment improves fabric final hand and feel through relaxed processing conditions, with full traceability of the washing parameters.

Weight reduction: “silkening” polyester

AQUARIA® delivers specialized weight reduction treatments for polyester fabrics, applicable to both woven and knitted constructions. This process achieves unique soft and silky hand characteristics, operating under relaxed conditions with low water consumption, ensuring always optimal results with fast production speeds.

Woolen fabric

The system handles any woven or knitted woolen and blended fabric, providing rapid scouring and light milling/fulling effects. This 100% green process improves fabric final hand and feel while offering controlled light milling/fulling when required, all achieved through low water consumption and relaxed processing conditions.

Unique silk effects

AQUARIA® treats any woven or knitted silk fabric, whether dyed or prepared for dyeing, to achieve unique aspect and touch characteristics, enhanced softness, and aged appearance effects. The treatment significantly improves fabric final hand and feel through low water consumption processing with relaxed conditions.

Washing after dyeing, and after reactive printing

Providing comprehensive washing solutions for any woven or knitted fabric, AQUARIA® can handle any type of fabric, both woven and knitted, after dyeing, conventional printing, or digital printing.

The system offers a completely safe fabric handling, low water usage, improved color fastness, and effective removal of excess ink and thickener in a relaxed process, which also offers improvements on the final hand feel, and allows for reaching high levels of productivity with minimal water consumption.

Washing after dyeing

AQUARIA® provides comprehensive washing solutions for any woven fabric after dyeing processes, focusing on improved color fastness achievement. The treatment utilizes relaxed processing with low water consumption to deliver higher color fastness levels and enhanced fabric final hand and feel.

Digitalization and Industry 5.0: intelligent process control

Digitalization represents the beating heart of the AQUARIA® ecosystem. The centralized control system with touch screen and user-friendly interface allows complete management of all operating parameters, with recipe storage and real-time monitoring of process data and energy consumption.

Integration with existing monitoring systems through standard Industry 5.0 protocols (OPC-UA, Open Platform Communications-Unified Architecture) enables direct access to all operating parameters, while the integrated diagnostic system provides immediate information for quick and effective solutions. Automatic reporting and data visualization, both local and remote, complete a digital ecosystem that transforms quality control from reactive to predictive.

Sustainability: beyond compliance, towards environmental excellence

AQUARIA® redefines the concept of sustainability in the textile sector through measurable and concrete results. Analysis of data from operating systems has demonstrated that AQUARIA® enables:

• Superior water efficiency: possibility of starting with only 500 liters of water, zero-water discharge for processes such as the eco-bleaching, and water consumption figures which remain in the range of 2-5 L/kg for most other processes.

• Zero water: completely closed processes for specific treatments in which all the water can be recycled and reused, with zero discharge (eco-bleaching and some enzymatic treatments).

• Energy saving: reduction of energy consumption up to 30% through an efficient recirculation system.

• Ecofriendly chemical approach: processes that eliminate the use of harmful substances such as oxidizing products, caustic and chlorine, or replace chemical solvents with natural and biodegradable washing agents.

• Integrated recycling: modular water recovery system with reuse between different modules to minimize overall impact.

Industrial scale tests have confirmed the environmental effectiveness of the system, including the CLIMA certification for low environmental impact textile machinery.

Quality and versatility: a system for every need

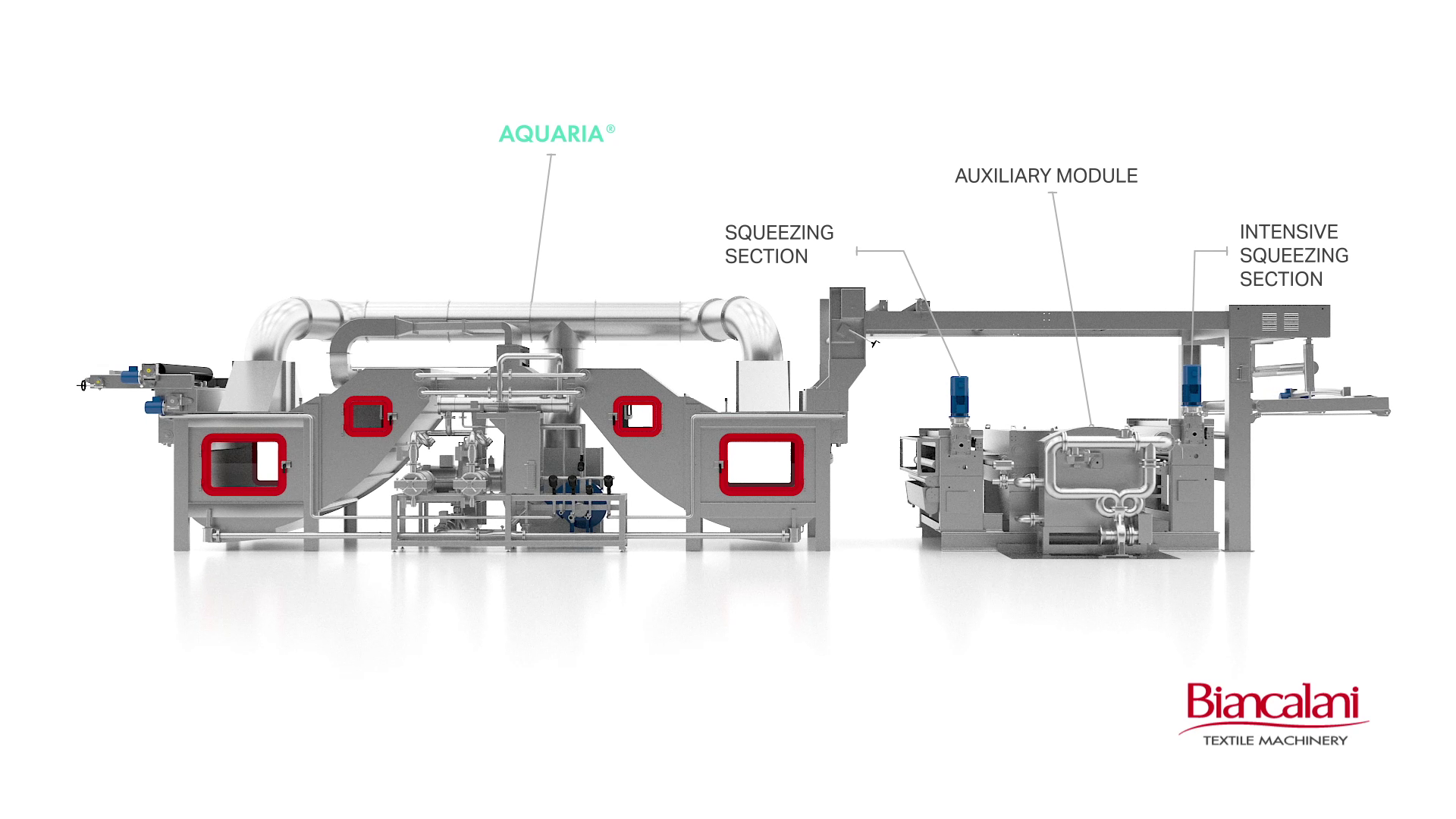

The modularity of AQUARIA® allows customized configurations for every specific production requirement. From the standard multi-purpose configuration, to dedicated lines for washing and post-printing/dyeing finishing, each configuration is designed to optimize performance and flexibility.

The technical specifications testify to this versatility:

• Working widths up to 3600 mm

• Production speeds up to 80 meters/minute

• Fabric treatment speeds up to 600 meters/minute

• Variable fabric accumulation from 20 to 500 meters

• Operating temperatures up to 98°C

• Water usage lower than 1 L/kg for zero-water processes, and ranging between 2 and 8 L/kg for most treatment, with starting water level of just 500 liters for the main module.

Flexible production: agility at the service of the market

The modern textile industry requires production flexibility to respond quickly to market variations and customization requirements. AQUARIA® responds to this challenge through:

• Modular configuration: the possibility of combining main and auxiliary modules allows adapting the line to different process types without production interruptions.

• Customizable recipes: each process can be stored and recalled instantly, allowing rapid product changes and optimization for small and medium series.

• Dynamic control: real-time adjustment of all parameters enables immediate adaptations to customer specifications or raw material variations.

The future starts today: vision and perspectives

AQUARIA® represents more than a technological solution: it is the concrete manifestation of a vision that sees the textile industry as the protagonist of the transition towards a sustainable and digitalized production model. In a sector where competitive pressure and environmental regulations are constantly intensifying, investing in technologies like AQUARIA® means not only responding to current challenges, but anticipating future ones.

The combination of operational efficiency, environmental sustainability, and final product quality positions AQUARIA® as the strategic choice for companies that want to lead the sector transformation rather than suffer it.

Excellence is not by chance

Biancalani, with over sixty years of experience in textile innovation, once again confirms its commitment to R&D through AQUARIA®. This solution represents the perfect coordination between Italian manufacturing tradition and technological innovation, offering the global market a tool that establishes new reference parameters in terms of quality, sustainability, and efficiency.

AQUARIA® is a solution already adopted by textile producers from different sectors for applications requiring precision, traceability, and control of sustainability parameters. Data from active installations confirm technical feasibility and significant contribution to minimizing the environmental impact of continuous washing processes.

For textile producers, plant managers, engineers, and business decision-makers looking to the future, AQUARIA® is not just a technological choice: it is an investment in long-term competitiveness and environmental responsibility.

AQUARIA®: pimp up your fabric, power up your future.

For more information on AQUARIA® and Biancalani solutions, visit www.biancalani.com or contact our specialists for personalized consultation.

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.