Flexible approach

Flexible approach

Wool milling and scouring

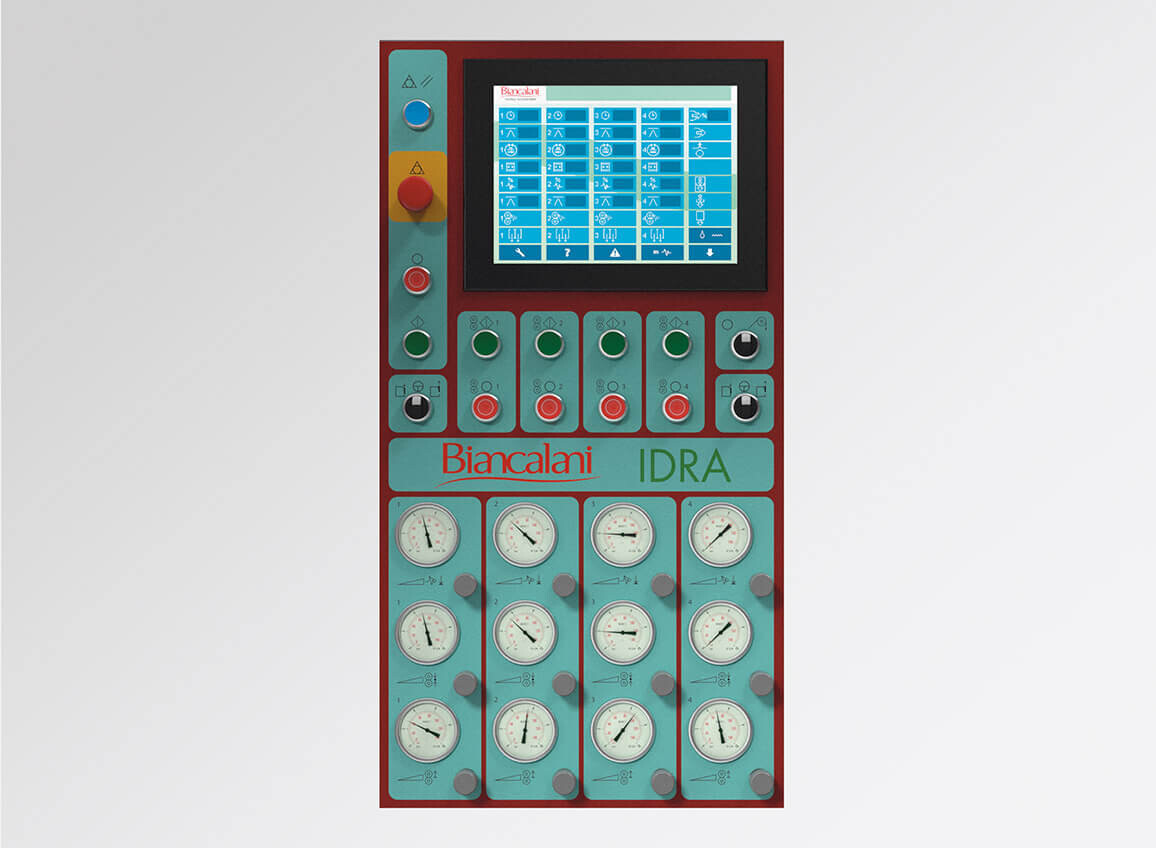

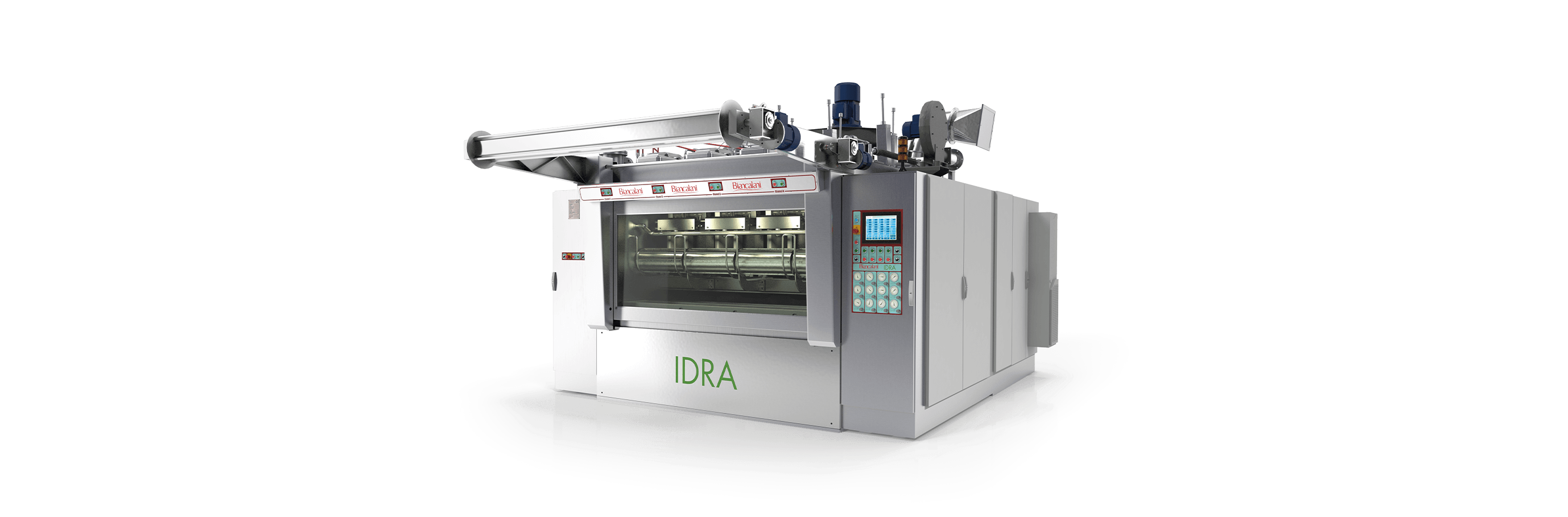

Biancalani IDRA, the state-of-the-art solution for flexible washing and milling of any type of woollen fabric.

Here’s IDRA

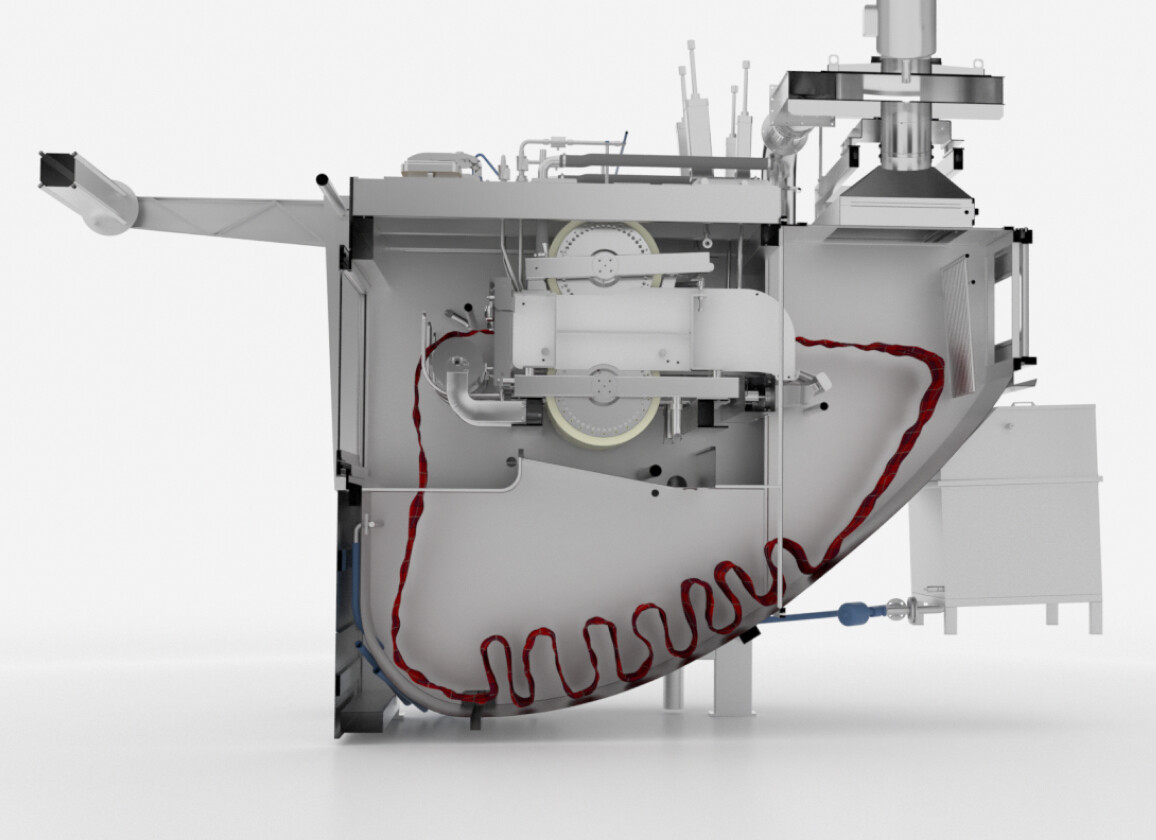

IDRA is the state-of-the-art solution for flexible combined washing and milling of any type of woollen fabric. Born from the tradition of quality and the expertise of Biancalani, IDRA overcomes the typical milling hurdles in woollen fabrics, such as overall variable lengths and the natural, uneven reaction of the fabric to the treatment itself. Each milling channel can be loaded with a different type of fabric, and by monitoring in real-time the shrinkage level, it will automatically stop when its milling cycle is completed.

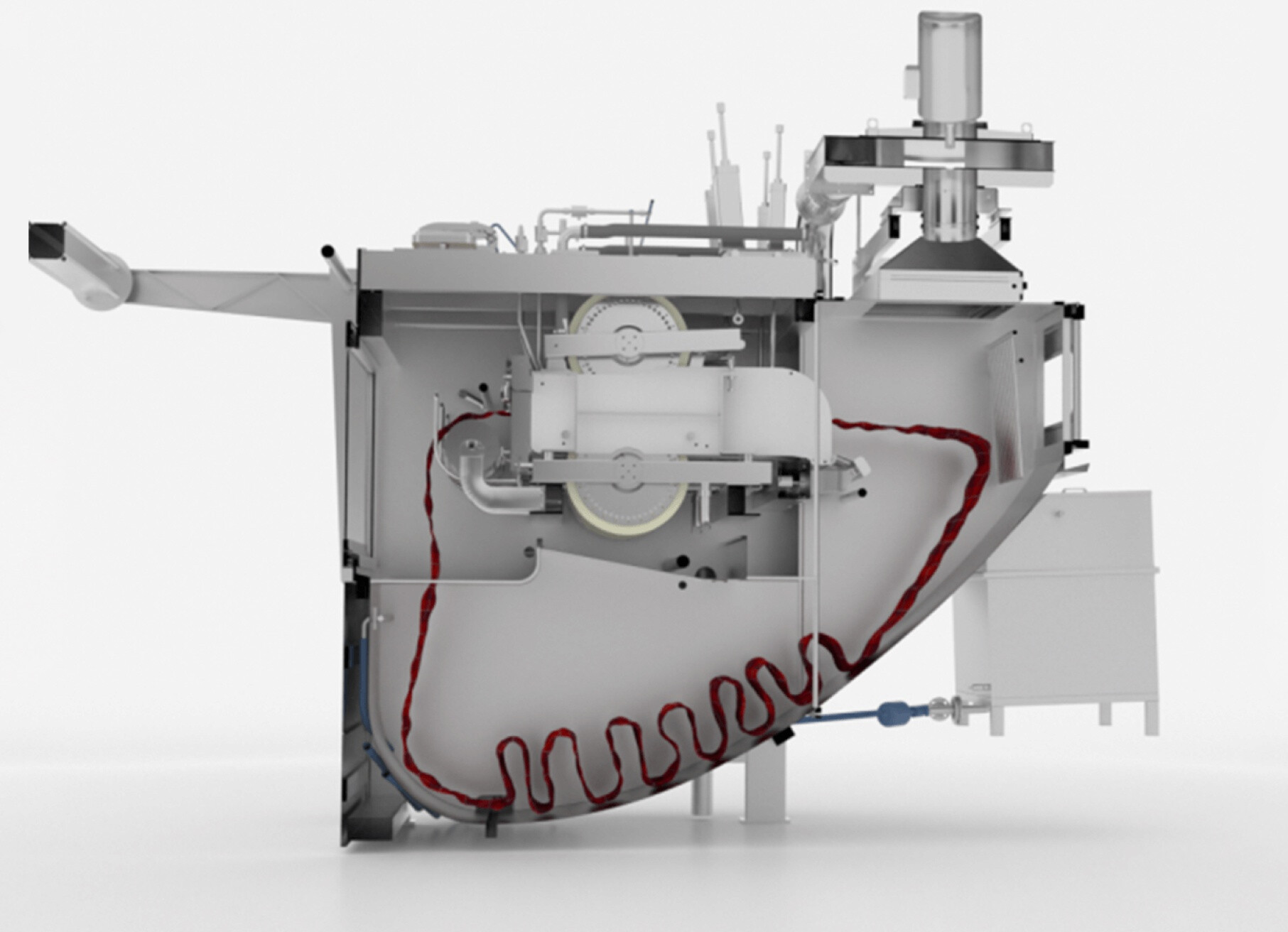

Safety and optimisation

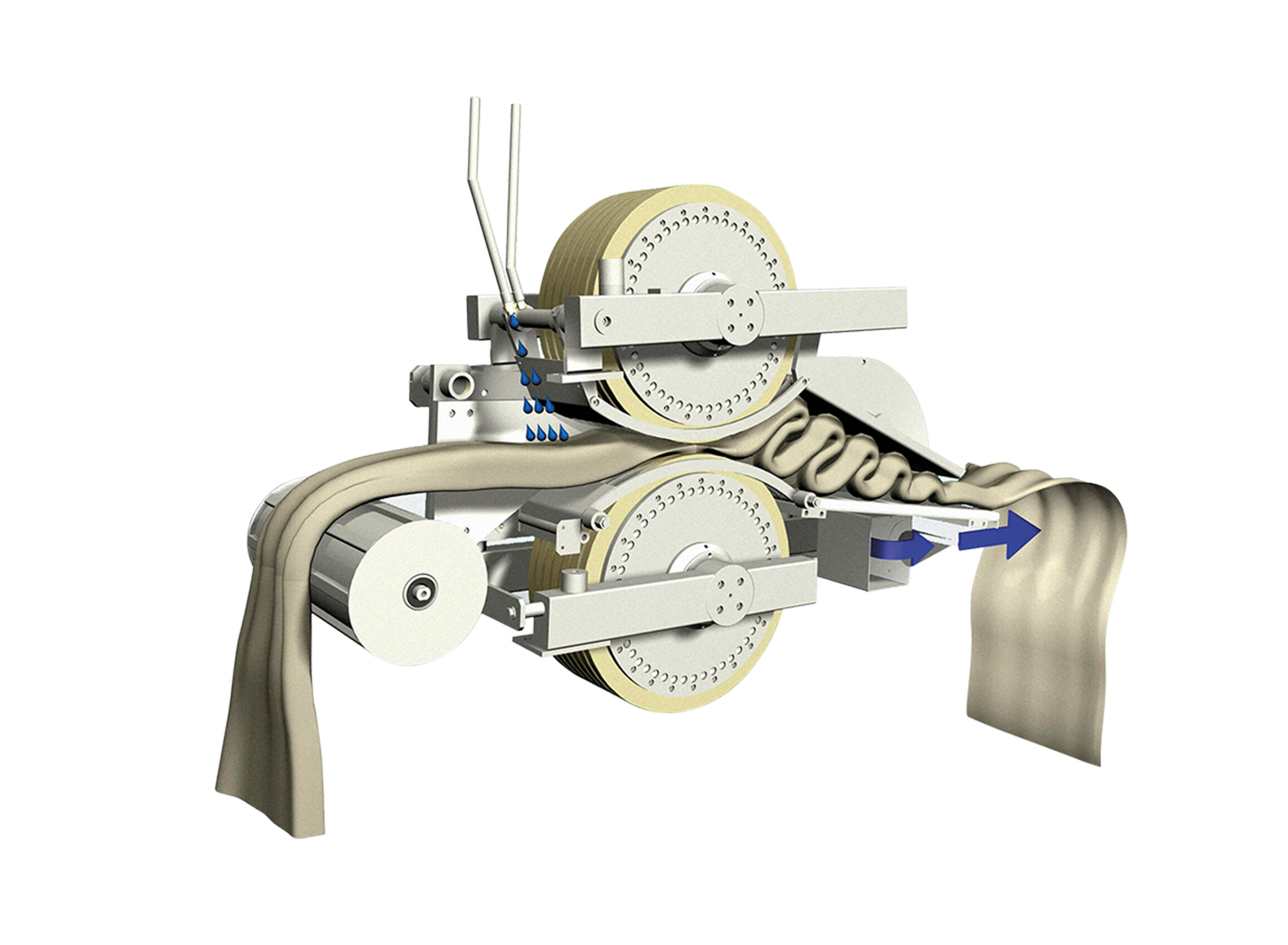

For each cylinder, the air-jet which repositions the fabric, the grooved covering in synthetic rubber which guides the fabric into the milling boxes, and the automatic optimization of the individually applied power which prevents from micro slippages, ensure efficiency and complete safety of the process. The programming of the pressure levels and the lightening of the upper cylinder, as well as the independent regulation of the adapter pressure of each individual milling box, allow for excellent customization of treatments and perfect repeatability over time.

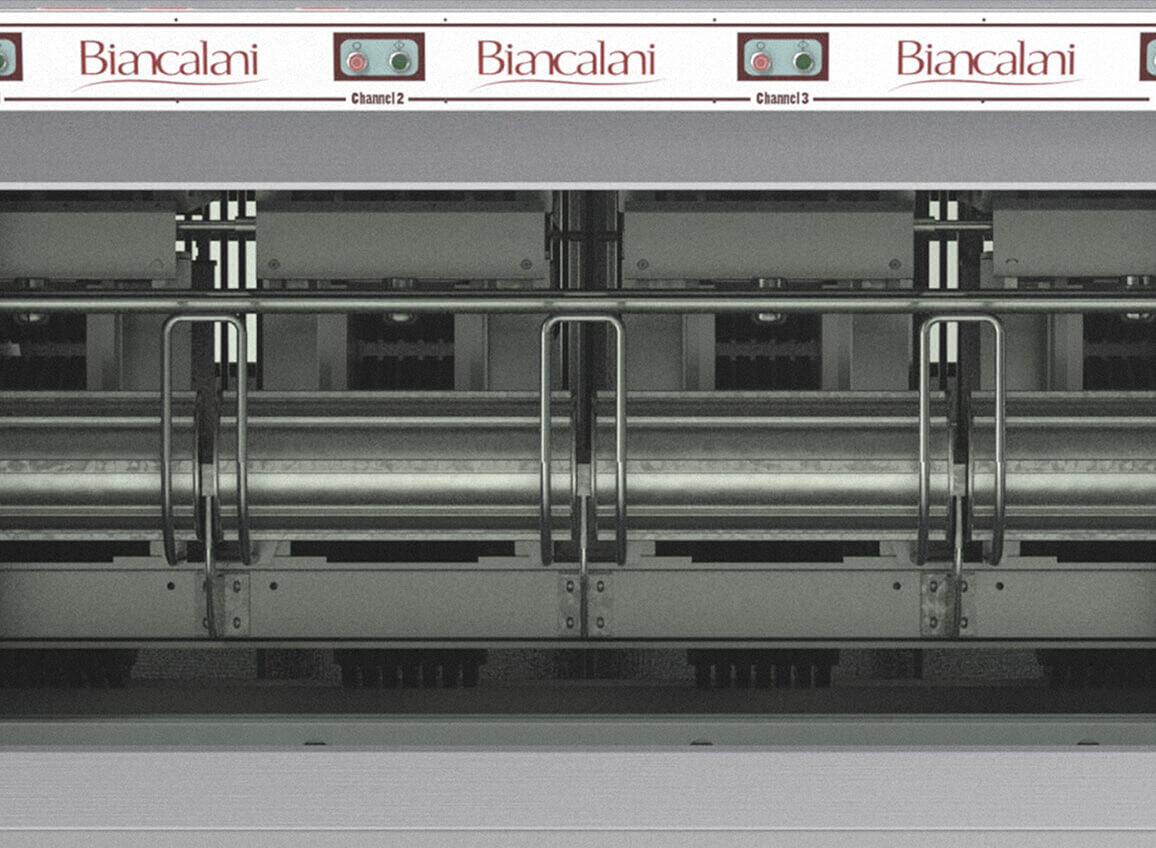

Flexibility and ease of maintenance

Users can set specific milling cycles for every type of fabric loaded, and obtain a superior qualitative result: within the same colour range, the automatic process will optimize different lengths of fabric in varying composition and weight. The systems also allows for maintenance intervention in individual channels, ensuring production continuity in the others.

Applications and processes

IDRA can be used to obtain perfect washing and milling results on any kind of woollen and wool-blended fabric, in weights ranging from 100 to 1200 grams per metre, woven and knitted, carded and combed, for a really wide range of applications, from men's and women's apparel, to automotive, home textile, and special-purpose materials (billiards table cloth, tennis balls…).

Technical specifications

IDRA 2 | IDRA 4 | |

|---|---|---|

Number of channels | 2 | 4 |

Loading capacity | 150 kg/channel | |

Treatment speed | 30-600 m/min | |

Distance between fabric | 50-170mm | |

Capacity of tank for chemical products | 2 x 300 L | 2 x 600 L |

Maximum water capacity of the vat | 1200 L | 2500 L |

Maximum water temperature | 60° C | |

Installed electrical power | 54 kW | 84 kW |

Average absorbed electrical power | 38 kW | 53 kW |

Dimensions (W x L x H from ground) | 2500 x 5080 x 2880 mm | 3750 x 5340 x 3360 mm |

Depth of foundation | 500 mm | |

Weight | 6000 kg | 9500 kg |

*The data shown can be changed at any time without prior notice due to product modification and improvement | ||

Download brochure

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.