Quality proof

Quality proof

Open-width drying, softening, finishing

Biancalani AIRO®24, the original dryer for continuous and open-width tumbling treatments of woven, non-woven, and knitted fabrics. A high-quality finishing style, which has no equal in the world. The AIRO® style.

Single · Duetto · Tandem · Triplex

Up to 80 metres per minute

Up to 2800 metres per minute

Up to 1400 kg per hour with a single machine

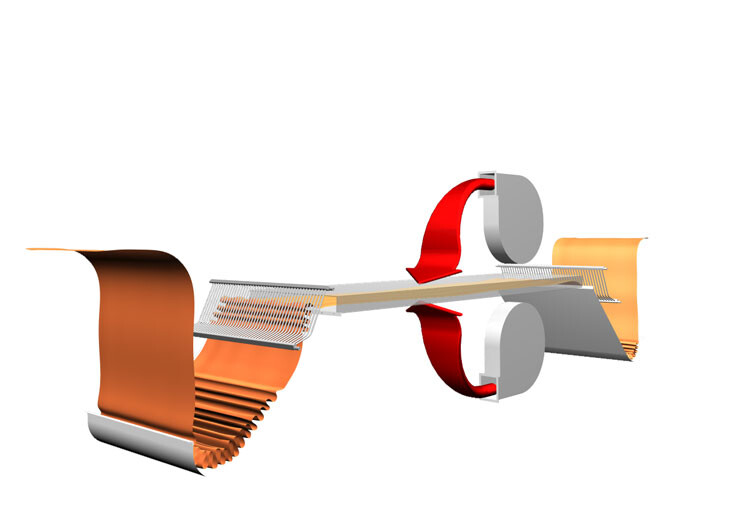

Here’s how it works

A set of airflows drive the fabric at very high speed in alternating directions, through the treatment channel, against specially-designed stainless-steel grills where it releases all its kinetic energy, acquiring body, volume, drape and better stability. This is the heart of AIRO® treatment, in a continuous and open-width process.

Air expertise from AIRO® experience

The experience of AIRO® led to the specific shape of the treatment channel of AIRO®24, conceived to maximize the efficiency of the process and designed without any internal moving part in order not to offer any resistance to the air or to the fabric, which can travel inside it at more than 2800 m/min (168 km/h). The large number (over 1000) of AIRO® installed has also enabled us to exactly define angle, distance and structure of the special grills, which are placed in front of the channel openings.

Fit for any job

Available with different production capacity, in SINGLE, DUETTO, TANDEM, and TRIPLEX versions, in partnership with the different sizes of AIRBOX, in line with squeezing and finishing padders, or following an AQUARIA washing range, AIRO®24 can satisfy every production need.

AIRO®24 can be fitted with a set of accessories, such as the STEAMING set at fabric entry, or the patented H-SHUTTER device that independently varies the width of each end of the treatment channel, increasing the performances and offering extreme flexibility for special applications.

In addition, the quick-threading MULTI-PANEL configuration with easy switch from one to two or three panels of fabric, and the TWIN-TUBULAR configuration, allow to fully exploit the processing power of the machine.

Suitable for every fabric

AIRO®24 can process any type of textile surface in a very wide range of materials, always with optimal results. From natural fibres and blends, to artificial (viscose, polyammide, Lyocell, Cupro, Modal) and synthetic ones, woven, knitted, non-woven, coated, or laminated, for different applications ranging from apparel to upholstery to home textile and technical applications. There are no limits in terms of weight and width. Results are obtained in complete safety and without defects.

What can AIRO®24 do for you?

- Airflow (AIRO®) tumble-drying and mechanical softening of wet fabric

- Mechanical, chemical-free softening, on dry fabric or with steam application

- Mechanical softening after application of chemical products

- Super soft and super swelling treatment of terry towel. Much more than tumbling!

- Single-pass high efficiency polymerization and softening of resin-treated fabric

- Cleaning treatment after bio-polishing and surface finishing

- Preparation for subsequent treatments such as shearing or coating

- Compaction, stabilization, relax

Which results will AIRO®24 deliver?

- Softness, volume, drape (AIRO® Hand)

- Swelling, perfect straightening and de-twisting of the loops on terry towels

- Hand breaking on particularly rigid fabric and laminated materials

- Dimensional stability, relaxation, increase in elasticity, resilience, and “sewability”

- Softness and uniformity of the surface on printed cloths

- Uniformity and absence of directionality on pile fabrics

- Casual look and wrinkled effect

- Opening of the chenille and three-dimensionality on jacquards

- Depth and richness of colours on yarn-dyed fabrics

- Peachy hand on emerized and brushed surfaces

- Grain-enhancement and natural/aged look on synthetic leather

- Increase of adhesivity and surface conductivity on non-woven substrates

- Higher transpiration capacity and/or increased hydrophilic properties for special applications

AIRO® hand label certifies the original AIRO® effect of the fabric finished in a Biancalani machine.

Technical specifications

Available working widths | Up to 3600 mm |

Production speed (fabric in/out) | 5-50 m/min (up to 80 m/min on request) |

Fabric treatment speed | Up to 2800 m/min |

Fabric inlet | Free / A-frame / in line |

Fabric delivery | Plaiter / A-frame / in line |

Maximum air temperature | 170°C |

Evaporation capacity | Up to 1400 kg/h |

Installed electrical power | Starting from 90 kW |

Installed thermal power | Up to 800 kW |

Average utilization of gas | steam | 30 Nm/h (gas) | 520 Kg/h (steam) |

Max consumption of compressed air | 500 Nl/min |

Dimensions (W x L x H) | From 3400 x 11700 x 3300 mm |

*The data shown can be changed at any time without prior notice due to product modification and improvement | |

Example configurations and lines

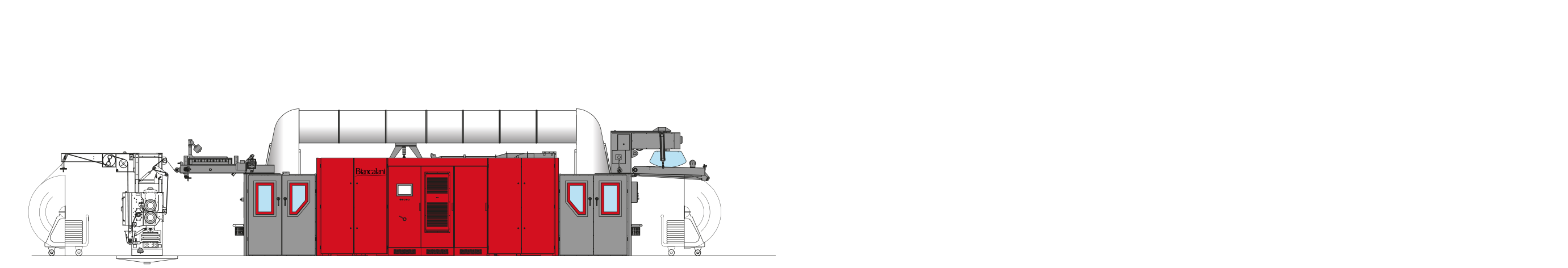

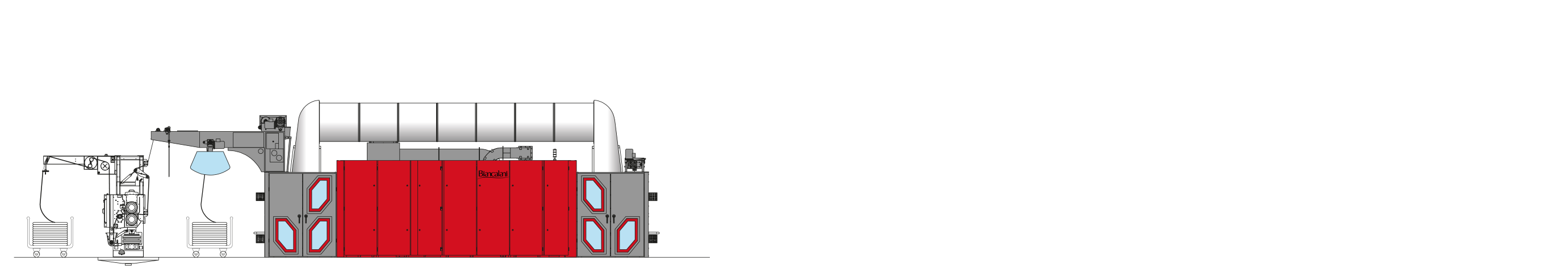

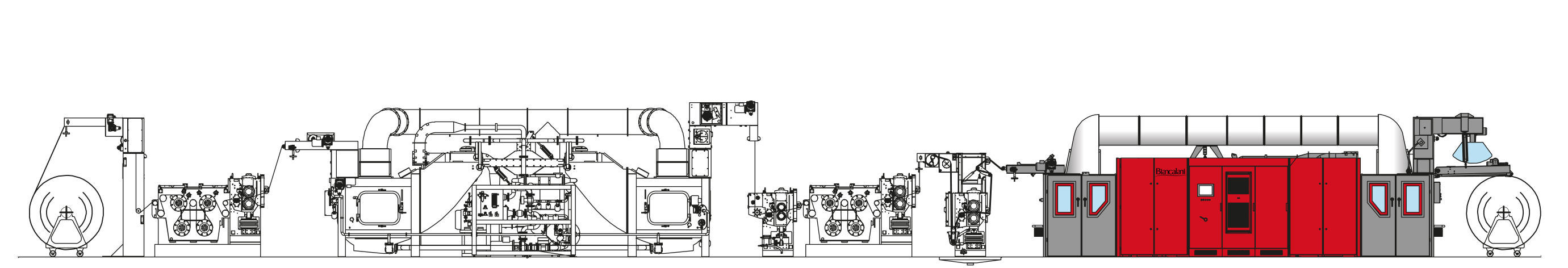

terry towel, large capacity, Airo24 Biancalani

GENERAL-PURPOSE CONFIGURATION Airo24 Biancalani

AIRO®24 DUETTO COMPACT DOUBLE-THROUGHPUT UNIT

DRYING AND FINISHING AFTER WASHING PROCESS

Download brochures

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.