A perfect partner

A perfect partner

Open-width (pre)drying

Biancalani AIRBOX, the modular high-efficiency open-width continuous drying unit, which can work either as integrated pre-drying system or independent high-capacity dryer.

What is AIRBOX?

AIRBOX is a continuous, compact and efficient open-width drying unit, patented by Biancalani, designed to work either as integrated pre-dryer for AIRO®24, or as a stand-alone system, which can be connected in line with other machines or used as independent dryer. The AIRBOX pre-dryer can considerably increase the productivity of any drying or tumbling line, while as stand-alone unit it offers an extremely favourable ratio between evaporation capacity and footprint size.

Technical Specifications

AIRBOX | AIRBOX XL | AIRBOX 4-6-8...(*) | |

|---|---|---|---|

Available working widths | Up to 3600 cm | ||

Production speed | Up to 3600 mm 5 - 50 m/min (up to 80 m/min on request) | ||

Fabric inlet | Free / A-frame / in line | ||

Fabric outlet | Plaiter / A-frame / in line | ||

Maximum air temperature | 200° C | ||

Installed electrical power | Starting from 30 kW | ||

Installed thermal power | Starting from 250 kW | ||

Number of heads | 1 | 2 | + 2 |

Total length of drying channel | 9 m | 15 m | + 12 m |

Evaporation capacity up to | 300 kg/h | 480 kg/h | + 360 kg/h |

Average utilisation of gas | 20 Nm3/h | 30 Nm3/h | + 10 Nm3/h |

Average utilisation of steam | 250 kg/h | 400 kg/h | + 300 kg/h |

Length | 2100 mm | 2700 mm | + 1200 mm |

Width (starting from) | From 4750 mm | ||

Height | 3300 mm | ||

*The data shown can be changed at any time without prior notice due to product modification and improvement | |||

Example configurations and lines

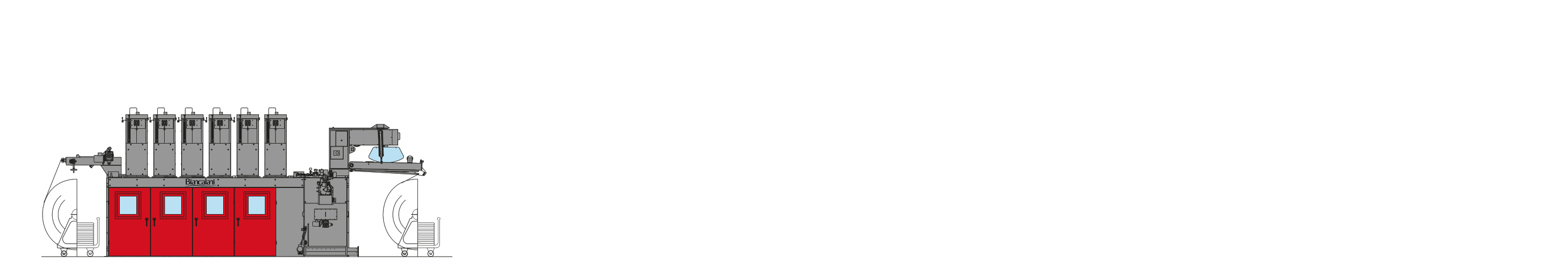

TERRY TOWEL

STAND-ALONE DRYER

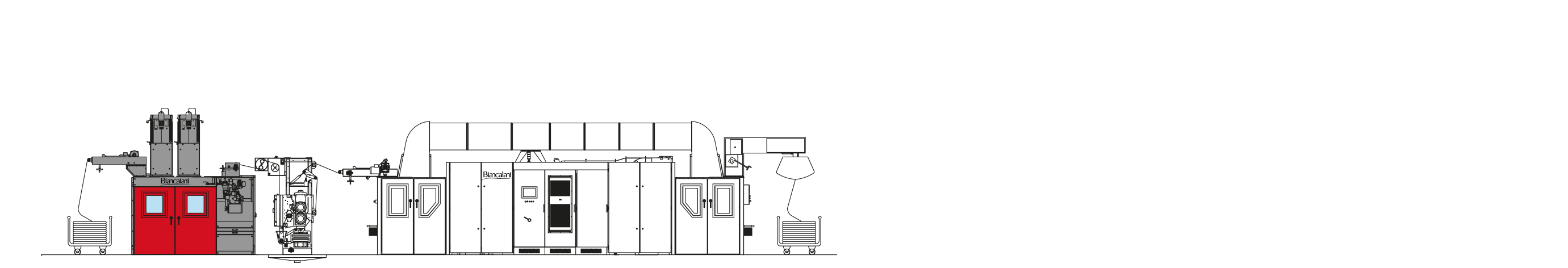

PIGMENT PRINT FIXING AND FINISHING

DRYING AFTER WASHING PROCESS

Download brochure

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.