About

Our past, your present, our future together

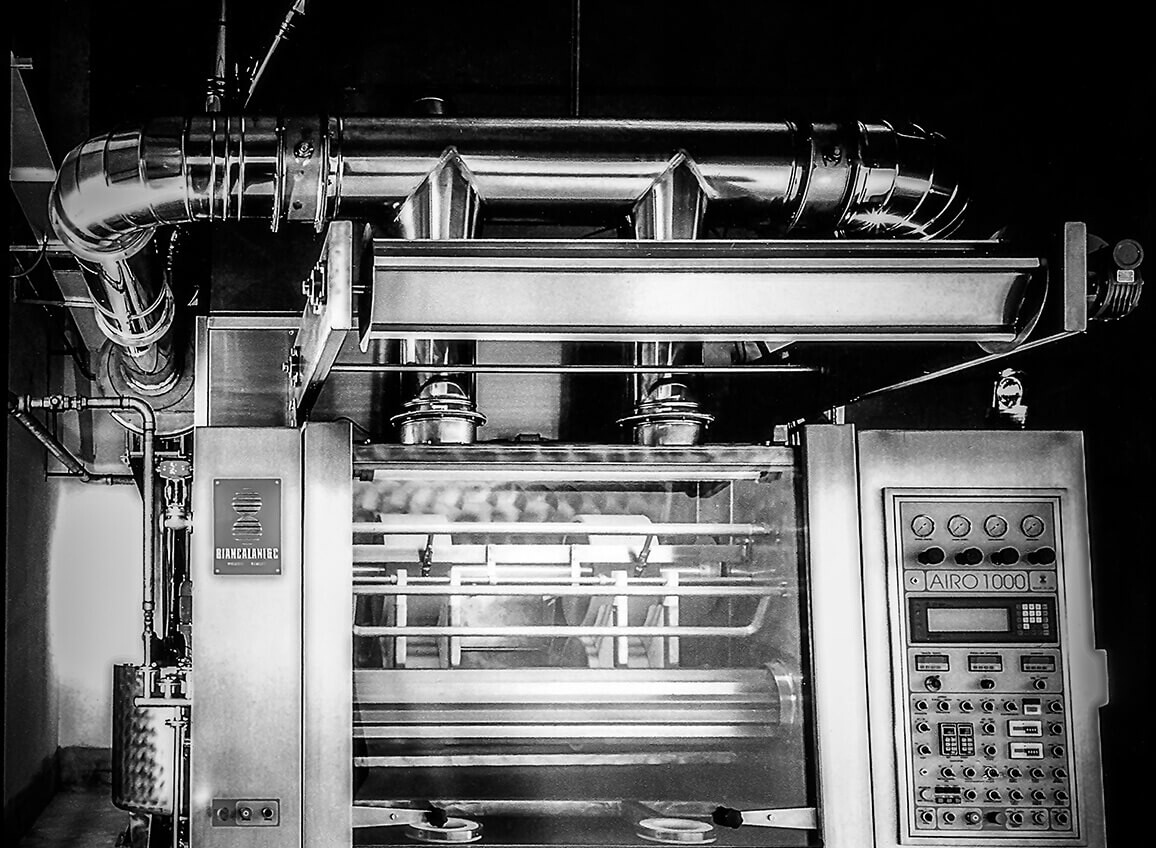

Biancalani Textile Machinery designs and develops quality solutions for fabric preparation and finishing, manufacturing 100% made in Italy machinery for the worldwide textile processing industry.

The passion and experience that we put into the design and production of these machines and lines together with our constant research towards efficiency and sustainability, have led us to become leaders in the market, gaining recognition and appreciation from customers all over the world. We offer effective and environment-conscious solutions for preparation and finishing of every type of fabric, in any composition and construction, for countless applications in the textile production area. All our staff here in Biancalani have one goal in mind: offer our customers the highest level of satisfaction. For this very reason, the concrete reliability of our solutions and the strength of our relationships with customers, from pre-sales technological consulting and testing, to technical assistance, are a source of huge pride for us.

Our core values

QUALITY

We strive to offer the highest quality to our customers as a support to help them guarantee quality to their own clients.

TRUST

We strongly believe in building long-term relationships with all our partners, giving them an active and leading role in our business strategy.

SUSTAINABILITY

We look for new approaches and solutions to social and environmental challenges in order to offer long-term value.

DETERMINATION

We develop technology that is geared towards concrete results: efficiency, effectiveness, and productivity.

Our mission

Retain our position as market leader through the continuous research of cutting-edge technology in the textile preparation and finishing sector thanks to the design and construction of textile machines that generate added value for our customers, satisfying – and often exceeding – their expectations.

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

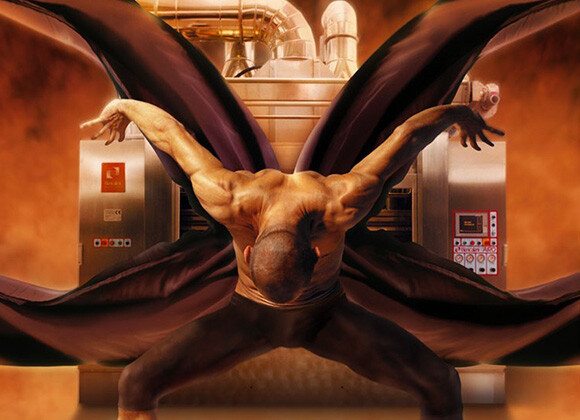

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.